Unique Tips About What Is The Difference Between A Coupler And Mechanical Splice

Pin On

Couplers and Mechanical Splices

1. Joining Forces

So, you're staring at a bunch of rebar, or maybe some fiber optic cables, and you need to connect them. Two options often pop up: couplers and mechanical splices. They both achieve a similar goal joining two things together but the way they go about it is actually quite different. It's like comparing a handshake to a hug. Both show affection, but one's a little moreinvolved.

Think of a coupler as more of a temporary, or semi-permanent, solution. It's generally designed to connect two similar items end-to-end, often with the ability to be disconnected later. A mechanical splice, on the other hand, usually creates a stronger, more permanent bond. It's designed for situations where you absolutely, positively don't want the connection to come apart.

And hey, let's be real. Nobody wants their bridge collapsing because someone skimped on the splices. That's why understanding the nuances between these two connectors is so important. Choosing the right one can mean the difference between a secure, long-lasting connection and a potential disaster waiting to happen. So, let's dive in and see what makes each one tick!

Before we get lost in the details, lets agree that a failed connection is never a good time. A wobbly bookshelf? Annoying. A critical support beam? Catastrophic. We need to get this right, and understanding the subtle (and not so subtle) differences is the first step.

What Exactly Is a Coupler?

2. The Connector with Options

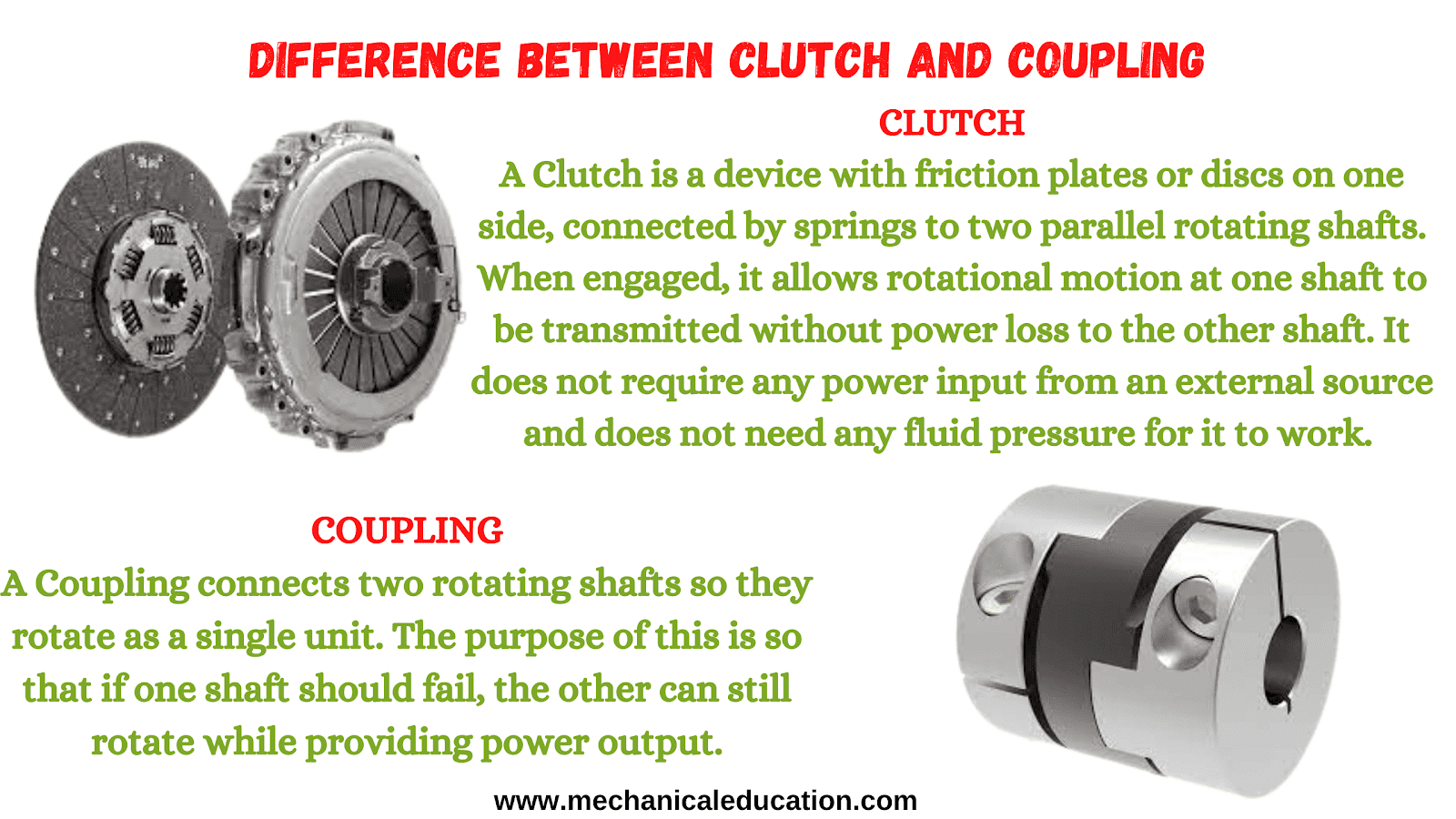

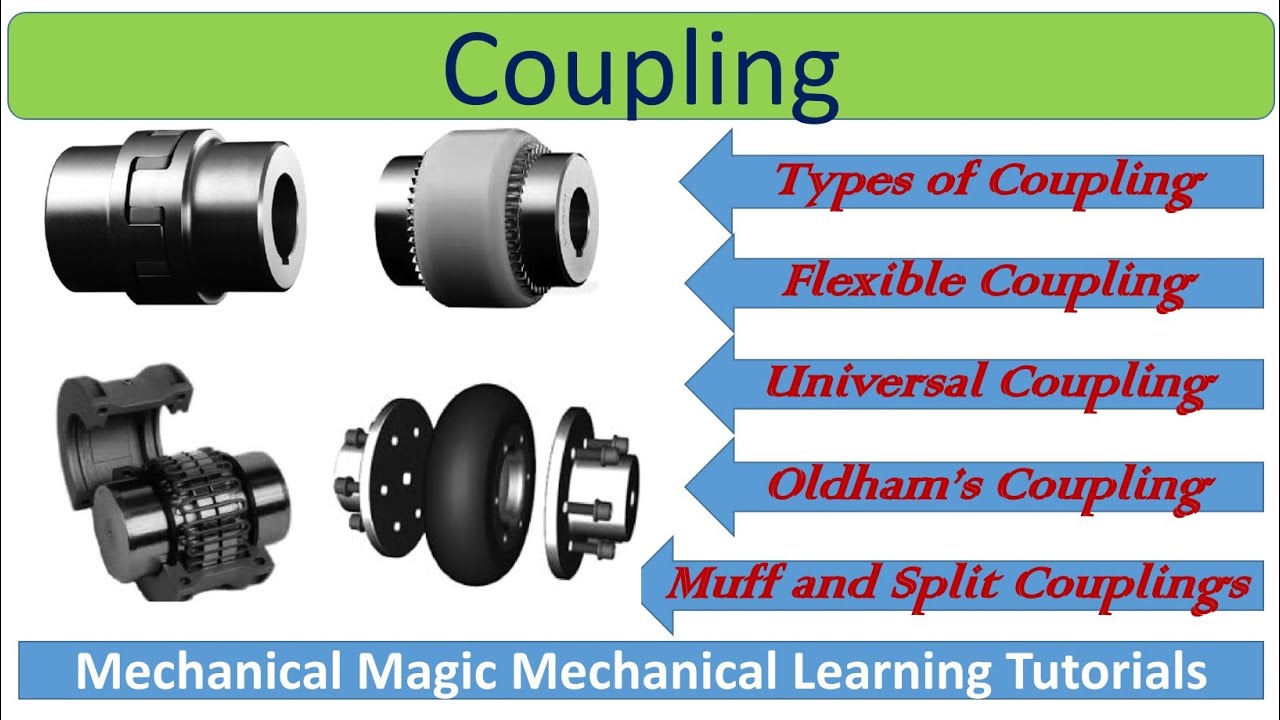

A coupler, at its heart, is a connector. It's that simple. It's a device used to join two shafts, pipes, or even optical fibers, allowing for the transfer of power, fluids, or light. The key characteristic of a coupler is often its potential for disassembly. Think of plumbing: you might use a coupler to connect two pipes, and if you need to make a repair later, you can usually unscrew it and separate the pipes.

Couplers come in all shapes and sizes, designed for a wide range of applications. Some are rigid, providing a solid connection, while others are flexible, allowing for some misalignment or movement between the connected parts. Consider the coupler that joins your car's steering wheel to the steering column it's designed to absorb some vibrations and allow for a smooth driving experience. That's not something you'd get with a rigid connection!

The beauty of a coupler often lies in its versatility. You can find them made from various materials, from metals like steel and aluminum to plastics and even ceramics. The choice of material depends on the application and the environment in which the coupler will be used. A coupler used in a corrosive environment, for example, would need to be made from a corrosion-resistant material.

Consider audio cables, too. Those little RCA couplers (remember those?) or even HDMI couplers let you extend cables without needing to replace the whole thing. Super handy when you're trying to set up your home theatre and realize your cables are just slightly too short. Been there, done that!

Decoding Mechanical Splices

3. The Permanent Kind of Connection

Now, let's talk about mechanical splices. These are all about creating a permanent or near-permanent bond. They're often used in situations where a strong, reliable connection is absolutely crucial. Think of reinforcing steel (rebar) in concrete structures. You wouldn't want those connections coming apart, would you?

Mechanical splices typically involve some form of mechanical gripping or clamping to hold the two pieces together. This might involve using bolts, screws, or even specialized gripping mechanisms. The goal is to create a connection that's as strong, or even stronger, than the original material itself.

Unlike couplers, mechanical splices are generally not designed to be easily disassembled. Once they're in place, they're meant to stay there. Trying to take them apart can often damage the connected pieces or the splice itself. This permanence is what makes them ideal for applications where long-term reliability is paramount.

Picture the splicing of fiber optic cables deep underground. These connections need to withstand environmental changes, ground movement, and just plain time. The goal is to make the splice almost invisible, so that light continues to travel along the cable without interruption. That kind of precision calls for a robust mechanical splice, installed by skilled technicians.

The Key Differences, Laid Bare

4. Spotting the Separations

Okay, let's get down to the nitty-gritty — or rather, let's skip the "nitty-gritty" and go straight to the key differences. The biggest one is probably the intended lifespan and ease of disassembly. Couplers offer more flexibility and potential for future adjustments, while mechanical splices are designed for permanence and strength.

Think about it this way: if you're building a temporary structure, like scaffolding, you'd likely use couplers to connect the pipes. This allows you to easily dismantle the structure when you're finished. But if you're building a skyscraper, you'd rely on mechanical splices to ensure the rebar connections can withstand the immense loads and stresses.

Another key difference lies in the installation process. Couplers are generally easier to install and require less specialized equipment. Mechanical splices, on the other hand, often require specific tools and expertise to ensure a proper and reliable connection. This is especially true for applications like fiber optic splicing, where precision is absolutely essential.

Ultimately, the choice between a coupler and a mechanical splice comes down to the specific application. What are you connecting? How strong does the connection need to be? How long does it need to last? And how important is the ability to disconnect the connection later? Answering these questions will help you choose the right connector for the job. Don't just guess... measure twice, cut once (or connect once, in this case!).

Coupler Vs Coupling What's The Difference

When to Choose Which

5. Real-World Scenarios

Let's make this even clearer with some real-world examples. Imagine you're a plumber connecting two sections of copper pipe in a residential water system. You'd likely use a copper coupler. This allows for a secure connection that can be easily disassembled if you need to make repairs or modifications down the line.

Now, picture a construction crew building a bridge. They're using rebar to reinforce the concrete. They'd use mechanical splices to connect the rebar sections, creating a strong and permanent framework that can withstand the weight of the bridge and the traffic it carries. No one wants a bridge that's easily taken apart, right?

Consider the world of electronics. You might use a coupler to connect two coaxial cables for your cable TV. This allows you to extend the cable without having to replace the entire run. But if you're manufacturing a high-precision electronic device, you might use a mechanical splice to connect wires or components, ensuring a reliable and permanent connection that won't be affected by vibration or temperature changes.

And let's not forget fiber optics! While both couplers and splices are used in fiber optic networks, mechanical splices are critical for long-haul connections where signal loss must be minimized. Couplers are more frequently used for patching and distribution in data centers where reconfiguration is common.

Difference Between Splice And Connector YouTube

FAQ

6. Quick Clarifications

Still have some lingering questions? Let's tackle a few frequently asked ones.

Q: Can I use a coupler where a mechanical splice is recommended?A: Probably not. Mechanical splices are usually specified for a reason — typically strength and permanence. Using a coupler in such a situation could compromise the integrity of the connection and potentially lead to failure. Don't cut corners where safety is concerned!

Q: Are mechanical splices more expensive than couplers?A: Generally, yes. Mechanical splices often require more specialized materials and installation techniques, which can drive up the cost. However, the added cost is usually justified by the increased reliability and longevity of the connection.

Q: How can I tell if a connection needs a coupler or a mechanical splice?A: Consult the relevant building codes, engineering specifications, or manufacturer's recommendations for the specific application. These documents will usually specify the type of connection required based on the load, environment, and other factors. When in doubt, always err on the side of caution and choose the stronger, more reliable option.