Nice Tips About What Does MTO Mean

Decoding MTO

1. Unveiling the Mystery of MTO

Ever stumbled across the abbreviation "MTO" and felt like you needed a secret decoder ring? You're not alone! MTO can stand for a few different things, depending on the context. It's kind of like that one friend who has a million nicknames. Let's break down the most common meanings and see which one fits your situation.

First and foremost, in the world of business, and especially in manufacturing, MTO almost always stands for "Make to Order." This is our keyword and we'll be exploring it further. Other uses exist, but for the purposes of this discussion, our primary focus is on Make to Order.

Imagine you're ordering a custom-built guitar. You pick the wood, the hardware, the finish the whole nine yards. The guitar company doesn't have a warehouse full of identical guitars waiting to be shipped. Instead, they build your guitar, specifically to your specifications. That's Make to Order in action. It's a manufacturing strategy where production only begins after a customer order is received.

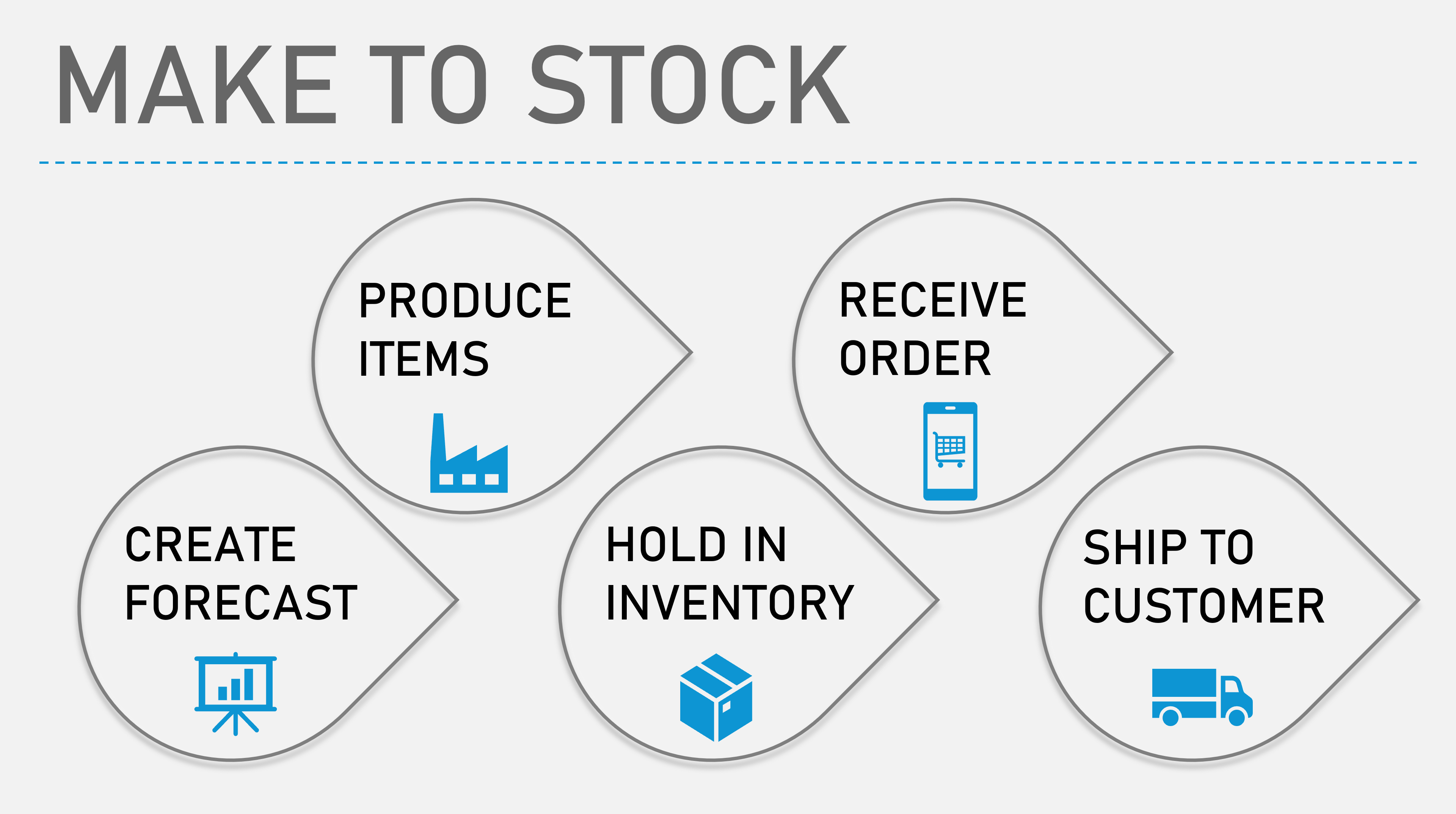

Its a pretty different approach from "Make to Stock" (MTS), where companies churn out products based on anticipated demand and fill up shelves in anticipation of sales. Think of your local supermarket; they stock shelves with goods they expect you to buy. MTO is far more personalized, albeit often with a longer lead time.

Make to Order (MTO)

2. Understanding the Nuances of MTO

So, why would a company choose the Make to Order model? Well, for several reasons. The most obvious is customization. When customers want something unique or highly specific, MTO is often the only way to go. Think tailored suits, specialized equipment, or even that funky phone case you designed online.

Another benefit is reduced inventory costs. Because products are only made when they're ordered, there's less risk of ending up with piles of unsold goods gathering dust in a warehouse. No more clearance sales just to get rid of excess inventory! This can be a huge advantage, particularly for businesses dealing with expensive or perishable items.

However, MTO isn't without its challenges. Lead times can be longer since production doesn't start until an order is placed. This requires careful planning and efficient supply chain management to minimize delays and keep customers happy. Nobody wants to wait six months for their custom guitar, no matter how awesome it's going to be.

Also, forecasting demand can be tricky. While you're not mass-producing based on predictions, you still need to anticipate the types of orders you're likely to receive so you can have the necessary materials and resources on hand. Think of it as forecasting trends rather than forecasting specific quantities.

Slippery Road Sign (USA) What Does It Mean? Learn For Your Permit Test

The Pros and Cons of MTO

3. Weighing the Advantages and Disadvantages

Let's recap the key advantages of Make to Order. Customization is a big one. Meeting specific customer needs can lead to higher satisfaction and stronger brand loyalty. Less inventory means lower storage costs and reduced risk of obsolescence. Plus, MTO can lead to higher profit margins, as customers are often willing to pay a premium for personalized products.

But there are downsides too. Longer lead times can frustrate customers, especially in a world of instant gratification. Increased complexity in production planning and supply chain management can add to overhead. And the potential for errors and rework is higher, as each product is essentially a unique prototype.

Choosing between MTO and other production strategies like Make to Stock really depends on the specific industry, product, and customer base. A small artisan shop might thrive on MTO, while a large consumer goods company would likely rely on MTS for its core product line. There is also Assemble to Order (ATO), which uses pre-made components to create a product. It is somewhere in the middle.

Think about a pizza place. They probably keep dough and sauce prepared (a bit like MTS), but they don't bake your pepperoni pizza until you order it. That's a blend of strategies, showcasing how companies often adapt and mix different approaches to optimize their operations.

Examples of MTO in Action

4. Real-World Applications of Make to Order

Beyond custom guitars and tailored suits, you'll find Make to Order in a wide range of industries. Aerospace companies often use MTO for specialized aircraft components. Construction firms rely on MTO for custom-designed building materials. Even some software companies offer MTO solutions, customizing their products to meet the unique requirements of their clients.

The rise of e-commerce has also fueled the growth of MTO. Online platforms make it easier for customers to design and order personalized products from the comfort of their own homes. Think of websites that let you create custom t-shirts, phone cases, or even furniture. MTO is becoming more accessible and mainstream than ever before.

Another interesting example is the automotive industry. While many cars are mass-produced using MTS, some manufacturers offer options for customizing certain aspects of the vehicle, such as paint color, interior trim, and optional features. This is a hybrid approach that combines the efficiency of MTS with the personalization of MTO.

And lets not forget the food industry! Many restaurants, especially those with customizable dishes (like salad bars or build-your-own-burger joints), operate on a modified MTO model. They prepare ingredients in advance but assemble the final product according to the customer's specific requests. Hungry yet?

MTO and the Future of Manufacturing

5. The Evolution of Make to Order

With increasing demand for personalized products and advancements in manufacturing technology, Make to Order is poised to play an even bigger role in the future. Technologies like 3D printing and advanced robotics are making it easier and more cost-effective to produce customized goods on a large scale.

Imagine a world where you can design your own shoes, furniture, or even appliances, and have them manufactured and delivered to your doorstep within days. That's the potential of MTO combined with cutting-edge technology. Its moving towards mass customization.

However, to fully realize this potential, companies need to invest in robust digital infrastructure, efficient supply chain management, and skilled workforce training. They also need to embrace data-driven decision-making to optimize production processes and minimize lead times. Think of it as building a smart, connected, and highly responsive manufacturing ecosystem.

So, the next time you hear the term "MTO," remember that it's more than just an abbreviation. It's a fundamental manufacturing strategy that's shaping the way products are designed, produced, and delivered to customers around the world. And who knows, maybe you'll even start designing your own custom creations!

FAQ About MTO

6. Answering Your Burning Questions

Q: Is MTO always more expensive than MTS?A: Generally, yes, because of the individual customization and smaller production runs. However, the lack of warehousing costs can sometimes offset this difference. It's really about value. Are you willing to pay more for a product perfectly suited to your needs?

Q: What types of businesses are best suited for the MTO model?A: Businesses that offer highly customizable products, deal with low-volume production, or cater to niche markets often find MTO to be a good fit. Think of custom furniture makers, specialized equipment manufacturers, or software developers creating bespoke solutions. But you should be aware of the demand fluctuations!

Q: How can companies improve their MTO processes?A: Streamlining communication with customers, investing in flexible manufacturing technology, and optimizing supply chain management are all key. Clear upfront agreements and realistic lead time estimates will keep everyone happy. Also try automating where possible and minimize human error.