Brilliant Info About How Do You Close A Metal Loop

Closing the Circle

1. Understanding the Basics

So, you've got yourself a metal loop that needs closing. Maybe it's on a piece of jewelry, part of a crafting project, or even something a little more industrial. Whatever the case, closing a metal loop securely and neatly is key to ensuring its functionality and appearance. But how do you close a metal loop correctly? Its not always as straightforward as it seems! There are a few methods, depending on the type of metal, the size of the loop, and the tools you have on hand. The "how do you close a metal loop" question really depends on the "what kind of loop is it?" and "what do you want it to look like?"

Think of it like this: trying to close a delicate wire loop with heavy-duty pliers is like using a sledgehammer to crack a nut — overkill! You'll likely damage the metal and end up with a messy, uneven closure. Conversely, attempting to bend a thick, sturdy loop with flimsy tools will probably result in frustration and a loop that refuses to cooperate. Therefore, selecting the right tool is a must.

Before we dive into specifics, let's get one thing straight: safety first! Always wear safety glasses to protect your eyes from flying metal fragments, especially if you're working with harder metals or using tools that could cause them to chip or break. Also, be mindful of your work surface. A sturdy workbench or table will provide a stable base for your work and prevent accidents. A cluttered workspace, however, can be a recipe for disaster.

And lastly, remember that practice makes perfect. Don't be discouraged if your first attempt isn't flawless. Closing metal loops is a skill that improves with time and experience. Start with some scrap metal to get a feel for the tools and techniques before tackling your actual project. This way, you can learn from your mistakes without ruining your precious materials. After all, a little preparation can save you a lot of headaches in the long run.

Choosing Your Weapon

2. Selecting the Right Tools for the Job

Now that we've established the importance of preparation, let's talk about the tools you'll need. The specific tools will vary depending on the type and size of the metal loop you're working with, but here are some essentials:

Pliers are your best friend when it comes to closing metal loops. You'll want a variety of pliers, including:Round-nose pliers: Ideal for creating and shaping loops, as well as making precise bends.Chain-nose pliers: Perfect for gripping and manipulating small objects, and for closing loops tightly.Flat-nose pliers: Useful for straightening and flattening metal, and for creating sharp bends.Bent-nose pliers: Great for reaching into tight spaces and manipulating loops at awkward angles.

A metal file is essential for smoothing out any rough edges or imperfections after you've closed the loop. Choose a file with a fine grit for best results. Also, don't forget a polishing cloth. Buffing the closed loop will give it a professional, finished look and remove any lingering scratches or marks. This is the step that elevates your work from amateur to artisan.

For thicker or harder metals, you might need a small hammer and an anvil or metal block. The hammer can be used to gently tap the loop closed, while the anvil or metal block provides a solid surface to work on. But be careful not to use excessive force, or you might damage the metal or distort the shape of the loop. Remember, finesse is key.

The Gentle Art of Closing Thin Metal Loops

3. Mastering the Technique

Closing thin metal loops, like those found in jewelry making, requires a delicate touch. The goal is to create a seamless closure without bending or distorting the wire. Here's how to do it:

Start by positioning the ends of the loop so they meet perfectly. Use your round-nose or chain-nose pliers to gently coax them into alignment. If the ends are uneven, use a metal file to smooth them out.

Next, use your chain-nose pliers to grip one end of the loop, and your round-nose pliers to grip the other end. Gently twist the pliers in opposite directions, until the ends of the loop are tightly pressed together. Be careful not to apply too much pressure, or you might break the wire. Small adjustments are better than forceful bends.

If you want to create a more secure closure, you can solder the ends of the loop together. Soldering involves using a small torch to melt solder (a type of metal alloy) onto the joint, creating a strong bond. However, soldering requires some practice and specialized equipment, so it's best left to experienced crafters. If you're new to soldering, consider taking a class or watching some online tutorials before attempting it on your own.

Finally, use your metal file to smooth out any rough edges or imperfections. Then, use a polishing cloth to buff the loop to a shine. This will give it a professional, finished look. Admire your handiwork! You've successfully closed a thin metal loop.

Taming the Beast

4. Working with Sturdier Materials

Closing thick metal loops, like those found in hardware or industrial applications, requires a bit more muscle. These loops are often made of harder metals, which means you'll need sturdier tools and a more assertive approach. But how do you close a metal loop when it's being stubborn?

Begin by preparing the ends of the loop. If they're rough or uneven, use a metal file to smooth them out. This will ensure a clean, strong closure. You might even need to use a hacksaw to trim the ends to the correct length.

Next, use your flat-nose or chain-nose pliers to grip the ends of the loop. Apply firm pressure to bend the ends together. You might need to use a hammer and anvil to help you. Place the loop on the anvil and gently tap the ends with the hammer until they meet.

For a more secure closure, consider using a metal fastener, such as a rivet or screw. Drill a small hole through the ends of the loop, and then insert the fastener. This will create a strong, permanent bond. Choose a fastener that's appropriate for the size and type of metal you're working with.

Finally, use your metal file to smooth out any rough edges or imperfections. Then, use a wire brush to remove any rust or corrosion. This will protect the metal from further damage. Youve successfully closed a thick metal loop!

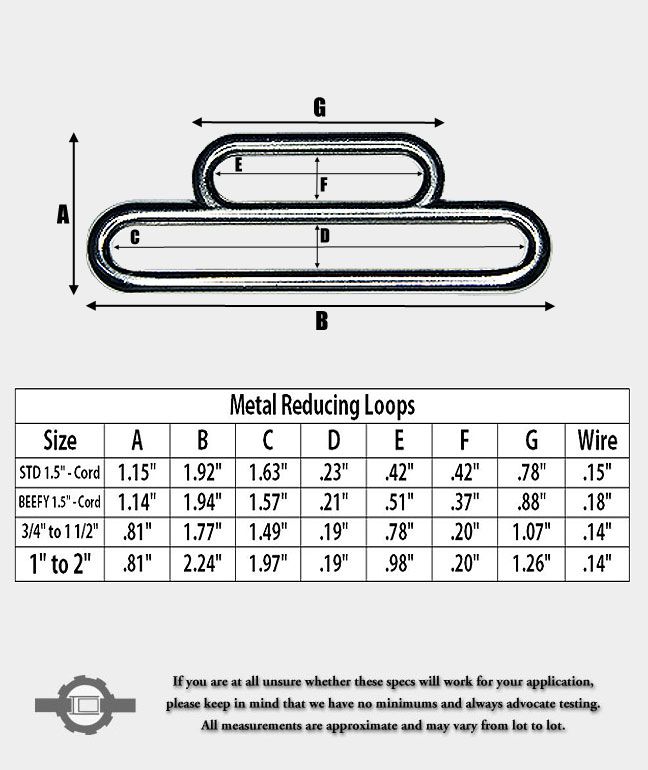

Metal Reducing Loops Loop, Metal, Hardware

Troubleshooting

5. Addressing Common Problems

Even with the best preparation and technique, things can sometimes go wrong when closing metal loops. Here are some common problems and how to fix them:

The loop is bent or distorted: This can happen if you apply too much pressure or use the wrong tools. To fix it, use your pliers to gently reshape the loop. You might need to use a hammer and anvil to straighten out any severe bends.

The ends of the loop don't meet properly: This can happen if the ends are uneven or if the loop is not properly aligned. To fix it, use a metal file to smooth out the ends. Then, use your pliers to gently coax the ends into alignment.

The metal is cracked or broken: This can happen if you're working with a brittle metal or if you apply too much force. Unfortunately, there's not much you can do to fix a cracked or broken metal. You'll need to start over with a new piece of metal. This is a good reminder to always wear safety glasses!

The closure is weak or insecure: This can happen if you don't use enough pressure or if you don't use the right fasteners. To fix it, try soldering the ends of the loop together or using a stronger fastener. And remember, a properly closed loop is a secure loop.

FAQ

6. Common Queries Addressed

Still have questions about closing metal loops? Here are some frequently asked questions:

7. What's the best way to close a metal loop without any tools?

Honestly, it's tough! You might be able to bend thin, soft wire closed with your fingers, but for anything sturdier, you'll really need pliers or other tools to get a secure and neat closure. Trying to force it without tools often leads to bent or damaged metal.

8. Can I use glue to close a metal loop?

While you could use glue, it's not recommended for a strong or lasting closure, especially if the loop will be under any stress. Glue is more likely to fail over time. Soldering or using mechanical fasteners like rivets are much more reliable options.

9. How do I prevent the metal from scratching when closing a loop?

Wrap the jaws of your pliers with masking tape or use pliers with plastic or nylon jaws. This will create a buffer between the metal and the pliers, preventing scratches. Also, work on a clean, smooth surface to avoid accidentally scratching the metal against your workbench.

10. Is soldering always necessary for closing metal loops?

No, soldering isn't always necessary. It depends on the application and the desired strength of the closure. For decorative purposes or light-duty applications, a well-formed mechanical closure (using pliers) might be sufficient. However, for applications where strength and durability are crucial, soldering is highly recommended.