Formidable Info About Why Is Closed Loop Better Than Open

Closed Loop Vs Open Cooling At Joanne Tindall Blog

Understanding Open Loop and Closed Loop Systems

1. What's the Difference, Really?

Okay, let's get down to brass tacks — but without using that exact phrase, of course! We're talking about open loop and closed loop systems. Imagine you're baking a cake. An open loop system would be like setting the oven timer for 30 minutes based on a recipe and walking away. You're hoping for the best, but you aren't checking to see if the cake is actually done.

Now, a closed loop system is more like having a smart oven that constantly monitors the internal temperature of the cake. If it senses the temperature isn't rising as expected, it adjusts the heat accordingly. This "feedback" mechanism is what makes closed loop systems, generally speaking, the more desirable option. Think of cruise control in your car; it adjusts the engine based on your speed, keeping you steady even on hills.

So, the key difference? Open loop systems operate based on a pre-set input, without any feedback about the actual output. Closed loop systems, on the other hand, use feedback to adjust their output, ensuring the desired result is achieved more accurately. It's the difference between hoping for the best and actively working to make the best happen. And let's be honest, who wants to just hope their cake turns out, right?

Consider a simple light switch. You flip it on (input), and the light comes on (output). That's an open loop. There's no sensor checking if the light is actually bright enough, or if the bulb is about to blow. But a closed loop system for lighting might adjust the brightness based on the ambient light in the room, saving energy and keeping things comfortable. See the advantage?

Why Closed Loop Systems Often Reign Supreme

2. The Accuracy Advantage

Let's face it, accuracy is king (or queen!). In most scenarios, we want things done right. This is where closed loop systems truly shine. The continuous feedback loop means these systems can compensate for disturbances and variations, leading to a much more precise outcome. Think about a thermostat in your home. It's constantly monitoring the temperature and adjusting the heating or cooling system to maintain your desired comfort level. An open loop system would just blast heat or AC for a set period, regardless of the actual room temperature. Brrr...or sweat, sweat, sweat!

Beyond just comfort, accuracy can be critical. Imagine a robotic arm assembling tiny components in a factory. A closed loop system ensures the arm moves to the exact required position, every single time. Errors could be costly with the open loop. It's the difference between a perfect product and a pile of scrap metal.

The feedback mechanism in closed loop systems also makes them much more robust. External factors like temperature changes, wear and tear on components, or even slight variations in input voltage can all affect the performance of a system. A closed loop system can detect and compensate for these variations, maintaining a consistent output. An open loop system, lacking this feedback, will simply be thrown off course.

Consider an industrial process where a precise amount of liquid needs to be dispensed. A closed loop system could use a flow meter to monitor the actual flow rate and adjust the pump speed accordingly, ensuring the correct amount of liquid is dispensed, even if the viscosity of the liquid changes. An open loop system would simply rely on a pre-set pump speed, potentially leading to inaccurate measurements and wasted materials. No one wants that!

The Downside of Complexity (and Cost!)

3. Not Always Sunshine and Rainbows

While closed loop systems often offer superior performance, they're not without their drawbacks. The biggest one? Complexity. Incorporating sensors, feedback loops, and control algorithms inevitably makes the system more complicated to design, implement, and maintain. It's like comparing a basic bicycle to a high-performance race car. Both can get you from A to B, but the race car requires a lot more specialized knowledge and upkeep.

And where there's complexity, there's often cost. The extra components needed for a closed loop system — sensors, controllers, actuators — add to the overall expense. Plus, the more intricate design and programming require specialized engineers, which can also increase costs. For some applications, the added expense might not be justified by the improvement in performance. A simple, reliable, and inexpensive open loop system might be perfectly adequate.

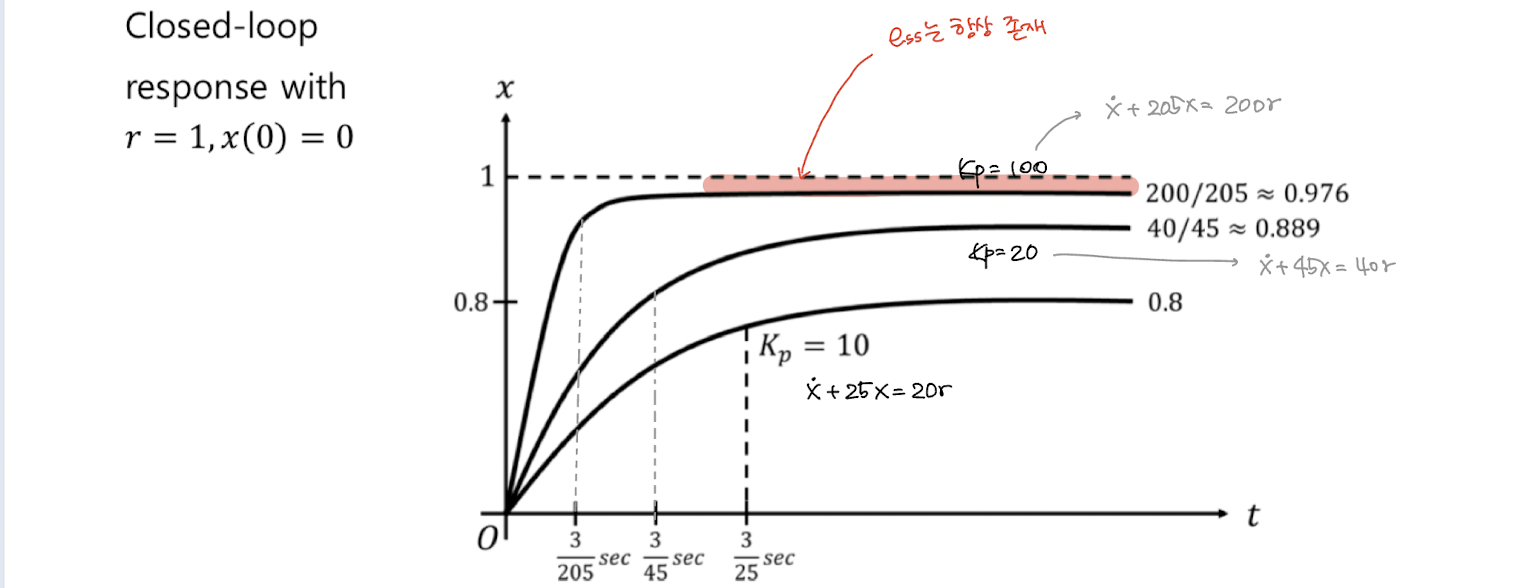

Another potential issue with closed loop systems is the possibility of instability. If the feedback loop isn't designed carefully, it can lead to oscillations or even runaway conditions, where the system goes haywire. Think of a microphone placed too close to a speaker — the feedback loop creates a screeching noise that just keeps getting louder. A poorly designed closed loop system can exhibit similar behavior.

The design of a suitable controller for a closed loop system can also be challenging. The controller needs to be carefully tuned to provide the right amount of correction without overshooting or undershooting the desired output. This often requires a deep understanding of the system dynamics and sophisticated control algorithms. So, while closed loop offers great benefits, bear in mind the implementation could be painful.

What Is Closed Loop Vs Open At Yolanda Jones Blog

When Open Loop Makes Sense

4. The Simplicity Factor

Despite their limitations, open loop systems still have a place in the world. In situations where accuracy isn't paramount or the cost of implementing a closed loop system is prohibitive, open loop can be a perfectly viable option. They're often simpler, more reliable, and less expensive to build and maintain. It's like choosing a hammer over a complex power tool for a simple task. Sometimes, the simpler tool is all you need.

Consider a simple toaster. It operates on an open loop principle — you set the timer, and the heating elements turn on for that duration. There's no sensor checking to see if the toast is actually toasted to your liking. But for the vast majority of people, a simple toaster is perfectly adequate. The small variability in toasting is not worth the added cost and complexity of a closed loop system.

Another scenario where open loop systems are often preferred is in applications where the system dynamics are well-understood and predictable. In these cases, it's possible to calibrate the open loop system to achieve a reasonable level of accuracy without the need for feedback. Think of a sprinkler system for your lawn. It operates on a timer, delivering a pre-determined amount of water. While a closed loop system could use soil moisture sensors to adjust the watering schedule based on actual needs, an open loop system can be perfectly adequate for most lawns.

Simplicity also translates to higher reliability. Fewer components mean fewer potential points of failure. Open loop systems are often less susceptible to noise and disturbances, and they don't require the complex control algorithms that can make closed loop systems prone to instability. This makes them a good choice for applications where robustness and reliability are critical.

Difference Between Open Loop Closed System With Vrogue.co

Practical Examples to Drive the Point Home

5. Real-World Applications of Each System

Let's solidify this with some real-world examples. Imagine a washing machine. A basic washing machine operates on a largely open loop principle. You select the wash cycle and the water level, and the machine runs for a pre-determined amount of time. There's no sensor checking to see if the clothes are actually clean or how dirty the water is. A more advanced washing machine might use turbidity sensors to detect the dirtiness of the water and adjust the wash cycle accordingly, creating a closed loop system.

Another example is a 3D printer. Early 3D printers used open loop control for moving the print head. The printer would simply move the head based on pre-programmed instructions, without any feedback about its actual position. This could lead to inaccuracies and defects in the printed object. More advanced 3D printers use closed loop control with encoders to precisely track the position of the print head, ensuring accurate and consistent printing.

Consider an older fuel injection system in a car versus a modern one. Older systems might use an open loop to inject fuel, relying on pre-set maps based on engine speed and load. This system doesn't adjust in real-time to things like changes in air temperature or altitude. Modern systems use a closed loop, with oxygen sensors in the exhaust stream, to measure the air-fuel mixture and adjust the fuel injection to optimize efficiency and reduce emissions. This allows the car to adjust to the environmental factor more consistently.

Finally, think about a basic electric fan. You turn it on, and it spins at a set speed. That's open loop. A smart fan, on the other hand, might use a temperature sensor to adjust the fan speed based on the room temperature, or even respond to voice commands. That's closed loop in action, adjusting based on its surroundings!